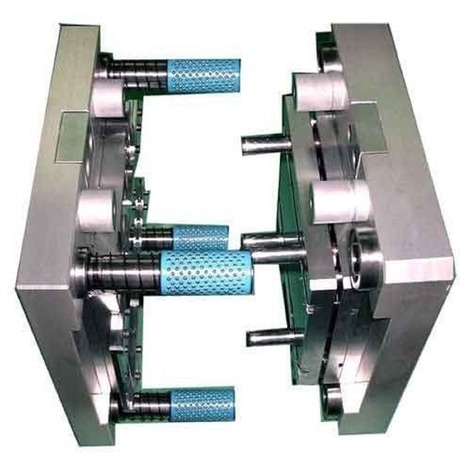

Injection Molding Machine

Engineering & Construction MachineryWe provide of high-quality range of vertical injection moulding machines where the entire injection moulding process occurs in the vertical direction. Both the clamping and injection units operate vertically, offering numerous benefits for insert moulding and the overall injection moulding process. In conventional injection moulding machines, the clamping unit opens and closes the mould horizontally during the operation cycle, while the injection unit, responsible for melting material and injecting it into the clamped mould cavity, also functions horizontally. This arrangement presents both advantages and disadvantages for the complete process. In contrast, vertical injection moulding machines feature a vertical layout, with the clamping and injection units stacked on each other. This configuration results in a compact physical footprint and provides several advantages over conventional horizontal machines, particularly in insert moulding, overmoulding, two-color moulding, and more.